Thermal Oxidation for Odor Control: Lessons from Real-World Industrial Installations

Odor problems in industrial settings vary widely. Some can be solved with simple chemical scrubbers or biological systems. Others require a more advanced solution—especially when the odor is strong, the emissions are variable, or the regulatory demands are high. In these cases, thermal oxidation for odor control is often the right choice.

Odor problems in industrial settings vary widely. Some can be solved with simple chemical scrubbers or biological systems. Others require a more advanced solution—especially when the odor is strong, the emissions are variable, or the regulatory demands are high. In these cases, thermal oxidation for odor control is often the right choice.

At Webster Environmental Associates (WEA), we work with clients to determine which technologies make sense based on site conditions. Thermal oxidation is one tool in our broader odor control toolkit. We apply it where it’s most effective—often in combination with other systems. Let’s go over what makes thermal oxidation successful and how we support clients through real-world installations.

Why Thermal Oxidation Works for Tough Odor Sources

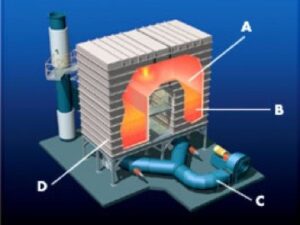

Thermal oxidation uses high temperatures to break down odorous compounds into simpler, less harmful gases. It’s especially effective for treating emissions with volatile organic compounds (VOCs), solvents, or other complex chemical mixtures. The process typically operates at temperatures between 1400°F and 1800°F.

In the field, thermal oxidizers perform well when:

- The emissions are difficult to treat using scrubbing or filtration.

- Odor loads fluctuate with process changes.

- Air permits require destruction rates over 95%.

The high heat provides consistent treatment, even in challenging conditions. That reliability is what makes this approach valuable in demanding industrial environments.

Real-World Examples of Thermal Oxidation in Use

Every facility has unique needs, but several types of operations commonly benefit from thermal oxidation for odor control. Here are some examples from projects we’ve worked on or supported in similar settings.

Example 1: Food Manufacturing Facility

A large cooking operation produces strong exhaust with grease, VOCs, and sharp odors. After testing and analysis, the site installs a regenerative thermal oxidizer (RTO). This unit uses ceramic beds to retain heat between cycles, improving fuel efficiency. It handles high-strength emissions and operates steadily during long production hours.

Example 2: Petrochemical Processing Site

A chemical plant faces emissions that include both odors and hazardous air pollutants. The solution includes a thermal oxidizer paired with a chemical scrubber. The oxidizer breaks down the VOCs, while the scrubber catches any acid gases that form. This combination helps the facility meet both odor and air quality targets.

Example 3: Hazardous Waste Incineration Plant

This site handles volatile compounds that require nearly complete destruction. The air permit calls for a destruction efficiency over 99%. A direct-fired thermal oxidizer does the job, operating at steady high temperatures. Continuous emissions monitoring confirms that targets are met year-round.

In each case, thermal oxidation becomes part of a larger system—designed to handle specific odors, chemicals, and compliance needs.

Design and Integration Considerations

Thermal oxidation systems must be designed with the full process in mind. At WEA, we evaluate each site’s airflow patterns, chemical loads, and infrastructure. We also help with decisions that affect energy use, safety, and long-term performance.

Important design factors include:

- Pre-treatment systems to help manage variable flow rates or humidity

- Ductwork and airflow controls for consistent delivery of exhaust to the oxidizer

- Options for heat recovery to lower fuel use

- Monitoring tools to track system performance and meet reporting requirements

We also help integrate oxidizers with existing treatment systems or recommend changes when needed.

Pairing Thermal Oxidation with Other Odor Control Tools

In most facilities, thermal oxidation is just one part of the odor control process. For best results, we often recommend combining it with other technologies. These might include:

In most facilities, thermal oxidation is just one part of the odor control process. For best results, we often recommend combining it with other technologies. These might include:

- Covers or enclosures to limit ambient air intrusion and reduce flow volume

- Mist eliminators or final-stage scrubbers to clean up the remaining exhaust

- Real-time odor monitors to catch changes in emission strength or system performance

This layered approach gives facility managers more control over odor problems and keeps systems running efficiently.

WEA’s Process for Complex Odor Solutions

At Webster Environmental Associates, we take a hands-on approach to every project. Our team starts with site visits and testing to understand the problem. From there, we help select the right mix of technologies. If thermal oxidation is the best fit, we assist with system sizing, permitting, and coordination with vendors.

Our services include:

- Detailed technical assessments of odor sources and airflows

- Equipment planning and layout support

- Guidance on monitoring and compliance tools

- Ongoing service, troubleshooting, and system updates

We understand that each facility has its own challenges. Our job is to offer practical, reliable solutions that match those needs—on budget and on schedule.

Connect With WEA for Smarter Odor Strategies

Thermal oxidation for odor control is a powerful tool when applied in the right setting. It handles complex, high-load emissions and meets strict regulatory requirements. But like any advanced system, it needs to be part of a thoughtful strategy.

If you manage a facility with strong industrial odors, Webster Environmental Associates can help. We bring decades of experience, deep technical knowledge, and a focus on real-world results. Contact us today to schedule a strategy session or site visit. We’ll help you find the most effective path forward.