Biofilters

Biofiltration is an odor treatment technology that utilizes biological processes as the treatment mechanism. Biofiltration utilizes naturally occurring microorganisms that grow on media to oxidize odor and air emission compounds to carbon dioxide, water, biomass, and other benign by-products such as chloride and sulfate. The by-products are emitted in the outlet air, drained from the biofilter, or consumed by the microorganisms. The biological activity in a biofilter is similar to the activities performed by the microorganisms in activated-sludge secondary wastewater treatment processes.

Biofilters require an acclimation period for microorganisms to become established. This acclimation period varies but is often cited as six weeks. Biofilters will acclimate to a wide range of odor concentrations. However, if the odor source is seasonal (i.e.- fluctuates with temperature), then it’s recommended to evaluate the performance of the biofilter during warmer weather when odor generation is typically higher.

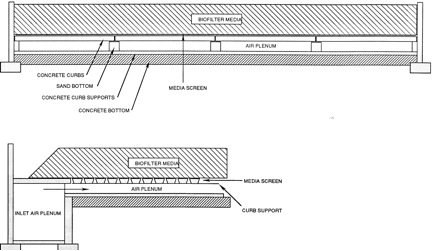

Typical biofilter sections are shown below. Biofilters work by routing odorous air through a porous filter media. The media represents the contact surface area, on which the microorganisms live, where the biological oxidation described above can take place. The key to effective biofilter operation is maintaining a healthy environment for these microorganisms to thrive in. The most important parameters for maintaining a healthy environment is moisture content and pH. The microorganisms need water to remain active, and the presence of water affects the transfer of the contaminants from the air to the media. The desired microorganisms thrive at neutral to moderately acidic pH levels.

Biofilter Operation

Biofilters are less control-dependent than chemical scrubbers, because the treatment system is more self-regulating. It is essentially a self-contained ecosystem, with very little instrumentation, that adapts to the compounds in the air being treated. Moisture levels must be controlled in the biofilter for it to function properly. Moisture content is assisted during dry periods by simple sprinkler systems and air humidification. The pH levels are often self-regulating within the ecosystem, and are assisted by proper choice of media. However, the reaction products in a biofilter treating hydrogen sulfide include sulfuric acid which lowers the pH of the media and drain water. Biofilter designs must include corrosion protection for the concrete and other downstream facilities due to the acidic nature of the drain water.

Biofilters are commonly used in wastewater collection and treatment applications and are well suited for treating waste streams that have relatively consistent loadings. They can handle moderate H2S concentrations but biotrickling scrubbers may be a better choice with higher concentrations. One of the biggest drawbacks to this technology is the relatively large footprint required compared to other technologies; however, recent media improvements have allowed for shorter residence times, deeper bed depths and smaller footprints. Biofilters are able to treat a wide range of contaminants and concentrations but do not immediately react to extreme loading fluctuations. They work best in situations where the loadings are relatively constant or where changes occur slowly. Biofilters will use approximately the same amount of power as carbon adsorbers and biotrickling scrubbers and slightly more than chemical scrubbers.

Modular Biofilter with Inorganic Media

Air streams with high concentrations of reduced sulfur compounds (RSC’s) such as mercaptans, dimethyl sulfide, dimethyl disulfide, diphenyl sulfide, carbonyl sulfide, and carbon disulfide can be treated in biofilters but the loading rates must be lower (and residence times must be longer) than those required to treat H2S. Required residence times can range from 20 seconds to 120 seconds depending on the contaminants and concentrations being treated.

Biofilter media types include wood-chip/bark media, soil/sand media, inorganic gravel-substrate media, lava rock, recycled glass and oyster shells.

Wood-chip/bark media generally possess a large diversity and density of microorganisms, accepts moisture relatively well, has low initial costs, and is readily available. The normal lifetime for properly selected wood-chip/bark media is 2 – 5 years depending on inlet loadings.

Soil media is a blended mix of soils, primarily sand/gravel-based. The primary advantage of soil media over wood-chip/bark media are their life expectancy. Soil has an estimated lifetime of over 30 years as a filter media. Soil media is denser than wood-chip/bark media and therefore resists compaction, it resists acidification because of its inherent pH buffering properties, it is less difficult to rehydrate after drying out, and generally distributes the air more uniformly than wood-chip/bark media. The primary disadvantage is that it requires a smaller loading per square foot, and therefore may require a larger footprint and significantly higher initial capital costs.

Inorganic media has grown in popularity and effectiveness over the past decade. It consists of strong, uniform sized gravel-like substrate with a proprietary exterior coating that does not compact as easily as organic media. This type of media may be used in open bed or modular designs because it allows greater media depth and a smaller footprint. The media typically comes with a 10 year life guarantee.

Applicable Treatment Processes

Major Design Considerations

Methods of air flow distribution and media support

Biofilters used to be designed with perforated pipes bedded in a layer of coarse gravel or stone. The air would pass through the perforations in the pipe through the gravel layer which supported the media and then through the media. These systems were plagued by uneven air distribution and plugged perforations. Now, most biofilters use manufactured air distribution and media support panels, fiberglass grating or a concrete slat system. These systems provide more consistent air distribution, are more corrosion resistant and provide easier means of media replacement.

Media selection

Which media to choose depends on many factors including: contaminant loadings and concentrations, footprint restrictions, project budget, accessibility to local sources, media replacement manpower limitations, etc. Inorganic media is typically purchased from manufacturers and will be significantly more expensive than organic media. Organic media may be purchased from manufacturers or obtained from local yard waste processing facilities, lumber yards or landscapers if they have the proper screening equipment. Media replacement frequency is affected by media selection, as mentioned above.

Moisture Control

Moisture control may be accomplished by pre-humidifying the inlet air and surface irrigation with spray nozzles. Moisture sensors in the media have not proven to be very reliable, therefore manual operator monitoring is typically used to ensure adequate moisture content.

Loadings

Loading of biofilters should be properly designed to prevent acid formation, corrosion problems, premature compaction of the media, short-circuiting the media bed, inadequate biological activity, and other problems which can result in sub-standard performance of the biofilter.

Corrosion Protection

Due to the formation of sulfuric acid as a byproduct in hydrogen sulfide treatment, corrosion protection should be included in the biofilter design. If the biofilter is constructed in or on concrete the concrete must coated or lined and the drain water piping must be constructed of corrosion resistant materials.