Thermal Oxidation

Thermal oxidation destroys odorous compounds and/or volatile organic compounds (VOC’s) in the air by heating them to about 1,400°F. The process works by subjecting the odorous air stream to the high temperatures in the presence of oxygen long enough to oxidize the odorous compounds. The process requires sufficient concentrations of combustible reactants in the air stream to sustain the combustion process in the thermal oxidation unit. Air streams with insufficient hydrocarbon concentrations require external fuel to sustain combustion. Fuel oil, natural gas, propane and digester gas are often used to supplement the combustion process.

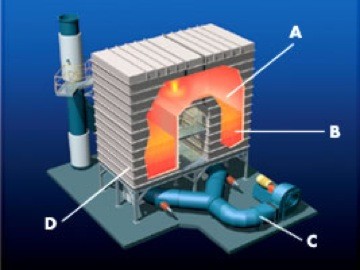

Regenerative Thermal Oxidizers (RTO’s)

Odor destruction is determined by time, temperature, and turbulence in the reaction chamber. Sufficient time for the oxidation to occur must be provided at the proper temperature to achieve high destruction efficiencies. Thermal oxidizers typically heat air streams to approximately 1,400oF for 1 – 2 seconds. Turbulence in the reaction chamber provides mixing and more uniform detention time.

RTO Cutaway View

Thermal oxidizers can be very expensive to operate due to supplemental fuel consumption. There are several fuel-reducing technologies available. The most common is the Regenerative Thermal Oxidizer (RTO). RTO’s reduce fuel consumption by preheating incoming air before routing it through the reaction chamber. They use multiple beds of ceramic media, through which the incoming air is preheated. Valving is sequenced so that each media bed captures heat from the exiting treated air in one cycle, and preheats the inlet air in the next cycle.

Ideally, RTO’s convert odorous compounds to carbon dioxide and water. In practice, the reactions are usually less than complete. Also, adding fuel to supplement the combustion process may add slightly odorous inorganic compounds such as nitrogen oxides (NOx) and sulfur oxides (SOx). Odor removal efficiencies are typically in the 90 – 99% range.

Advantages of this technology include:

- Best available control technology. Able to handle broad range of inlet concentrations

- Broad-spectrum control for all types of odor, performance is independent of inlet odor intensity

- Atmospheric dispersion is enhanced by warm exhaust.

Disadvantages include:

- Potentially high fuel costs

- Potential for NOx and SOx emissions

- Equipment is more complex and different than WWTP operators are accustomed to operating.

- O&M costs are typically higher than alternatives.

Applicable Treatment Processes

Sludge processing, such as dryers and storage vessels

Major Design Considerations

Heat capacity of air stream

Air stream must contain relatively high heat capacity to ensure operating efficiency.

Supplemental fuel source

A supplemental fuel source typically must be available to assist combustion.

Particulates

Particulates must be removed prior to the RTO to prevent plugging of the media.

Materials

Stainless steel inlet components should be specified because of potential corrosion in hydrogen sulfide laden air stream.