When Thermal Oxidation Is the Right Call: A Practical Guide for Complex Industrial Odors

Some industrial operations produce odors that are especially hard to control. These include emissions from processes involving solvents, petrochemicals, or other high-BTU compounds. For sites with strong, variable, or toxic emissions, basic odor control systems may not work well. In these cases, thermal oxidation is often the right approach.

Some industrial operations produce odors that are especially hard to control. These include emissions from processes involving solvents, petrochemicals, or other high-BTU compounds. For sites with strong, variable, or toxic emissions, basic odor control systems may not work well. In these cases, thermal oxidation is often the right approach.

At Webster Environmental Associates (WEA), we help clients decide when thermal oxidation makes sense. We evaluate the source, the odor strength, and any regulatory limits. Then we design a system that fits both the process and the site.

What Thermal Oxidation Does

Thermal oxidation uses high temperatures to break down odor-causing compounds in the air. These systems heat the process exhaust to a temperature where the compounds are converted into carbon dioxide and water vapor. Most systems operate between 1400°F and 1800°F.

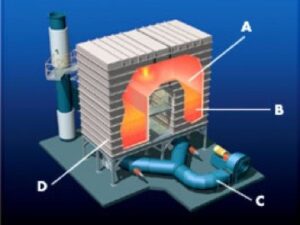

A thermal oxidizer typically includes a combustion chamber, burner, heat exchange, and control systems. Depending on the application, WEA may recommend a unit that includes energy recovery or allows for better control of exhaust flow.

This technology is often used when emissions contain volatile organic compounds (VOCs) or chemicals that do not respond well to scrubbing or biological systems.

When to Consider Thermal Oxidation

Thermal oxidation works best under specific conditions. We usually recommend it when:

- The process generates high concentrations of VOCs or other complex gases.

- The exhaust stream is too strong or variable for chemical scrubbers or biofilters.

- Regulatory requirements call for very high destruction efficiency.

- Safety or reliability is a concern, and a robust solution is needed.

In these situations, other methods may struggle to maintain performance. Thermal oxidation offers stable, predictable treatment when properly designed and maintained.

Benefits of Thermal Oxidation Systems

For the right application, thermal oxidation offers several advantages:

- High destruction rates of odor-causing compounds

- Reliable performance across variable flow rates

- Proven track record in industrial settings

It is also compatible with other systems, including capture and containment, or upstream pre-treatment. At WEA, we design thermal oxidizers to fit into a broader odor management strategy—not as stand-alone units, but as one part of a complete system.

Design Factors That Matter

Not every thermal oxidation system works the same way. The key to success is in the details. Our team looks at the full picture before recommending a design. This includes:

- Exhaust temperature and flow rate

- Type and concentration of compounds

- Available space and site layout

- Energy recovery needs

We may conduct field sampling and air modeling to confirm design inputs. If the process emissions vary, we account for that in the control strategy. We also help clients plan for proper ducting, source capture, and system monitoring.

Comparing Thermal Oxidation to Other Odor Control Options

In many projects, we look at multiple odor control approaches before choosing a path. Here’s how thermal oxidation compares to other technologies:

In many projects, we look at multiple odor control approaches before choosing a path. Here’s how thermal oxidation compares to other technologies:

Thermal Oxidation:

- High-temperature treatment of complex compounds

- Good for VOCs and solvents

- Reliable and effective for high-load conditions

Other Options:

- Biofilters: Better for steady, organic odors with low chemical loads

- Chemical scrubbers: Effective for acid gases or simpler odor profiles

- Carbon systems: Often used as polishers or backups

The choice depends on both the chemistry and the operational goals. At WEA, we help clients choose the system that offers the best long-term performance for their specific needs.

How WEA Supports Thermal Oxidation Projects

We provide a full range of industrial odor control services for thermal oxidation system planning and installation. Our team offers:

- Site visits to gather air quality data

- Emission profiling to select the right equipment

- System layout and integration with upstream collection and containment

- Controls planning for performance and compliance

- Post-installation support, including optimization and troubleshooting

Because thermal oxidizers are often part of more complex systems, we work closely with plant engineers and EHS staff to fit them into broader odor control plans. This includes upstream enclosures, ductwork design, and, when needed, additional treatment stages.

Work With WEA for Smart Odor Control

Thermal oxidation plays a critical role in treating tough industrial odors. It offers high destruction rates, reliable performance, and flexibility for sites with challenging emissions. But it’s not the only solution—and it’s not always the first.

That’s why we start with a careful evaluation. Our job is to match the right technology to your site, budget, and regulatory needs. We bring decades of experience and a practical approach to every project.

If your site is dealing with strong or complex odor sources, WEA can help. Contact us to schedule a technical review and learn whether thermal oxidation is the right call for your facility.